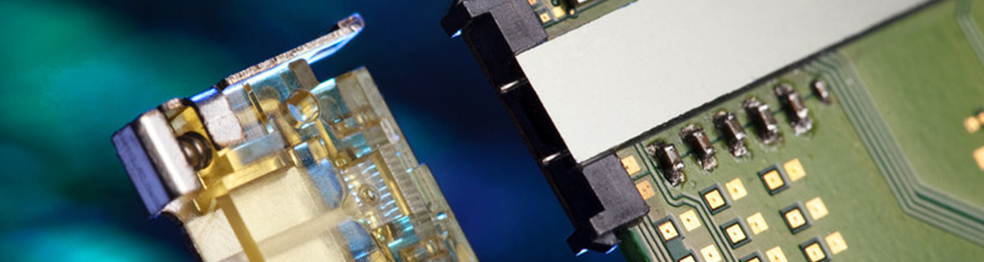

We have advanced capabilities for SMT/SMD assembly (also including FPC, Flexible-Rigid Printed Circuit, HDI

PCB), through-hole and mixed technology PCB assemblies. BGA down to 0.4mm pitch, 0201 component

placements and leadless devices assembly can also be available. High speed advanced Fuji SMT machines can

well support your high and strict requirements of PCB assembly, whatever in relation to mil-spec, network,

communication, health care, medical, musical instrument application. In terms of pass rate, we have done

99.8%. Our engineering team will discuss about assembly manufacturing process once we get your order.

The best work plan will be figured out and your PCBs are performed in quality online.

PCB Assembly Process

1.PCB Manufacturing

Our PCB factory built at 2009 year which is specializing in multi-layer, HDI with laser drill, Flex-rigid board, FPC,

metal core PCB fabrication, we have made above types PCB for many customers.

In our PCB factory, we can fabricate 20000 square meter per month to meet customers quantity requirement,

also have the QTA prototype fabrication line to ensure the customers quick turn lead time requirement.

To ensure your PCB quality, we will implement below reliability test before do the SMT or shipment:

PCB Quality Guarantee

*100% open and short E-test

* Micro-section Test

*Solderability Test

* Surface peelable Test

*Thermal Stress Test

*Impedance Test

*Ionic Contamination Test

*Inductance Test

*Plating thickness Test

*Plating Adhension Test

2. Screen Printing of Solder Paste onto PCB Board

Solder paste printing is applicable for placing appropriate amount solder paste onto PCB pads, in order to

ensure good circuit connection between SMT components and PCB pads and their mechanical strength.

Solder paste printing is the critical process of SMT. Metal template printing is conventionally applied so far.

According to related statistics, 60%~70% quality problems are caused by solder paste printing in premise

of quality guarantee of components and printed circuit board. Requirements of solder paste printing:

a. Place solder paste appropriately, evenly and uniformly. Solder paste shape is clear and neighbor shapes

do not connect. Solder paste shape is in compliance with that of pad, without any dislocation.

b. In general, the unit area solder paste amount should be 0.8mg/mm2, particularly 0.5mg/mm2 for

narrow-pitch components.

c. After solder paste printing, the shape has no heavy collapse and edges are trim. Plate surface is not allowed

to be contaminated by solder paste.

There are a large variety of solder paste with different alloy compositions, granularity and viscosity even for all

from one manufacturer. How to choose appropriate solder paste highly impacts the product quality and cost.

Now we use Loctite lead free solder paste. We have figured out Loctite solder paste is reliable to ensure good

product quality after process engineering test of its printability, demoulding, thixotropy, cohesiveness, wettability,

welding spot defect and residue.

3. Lead-free PCB Assembly

In light of environmental concerns and customer request, we can offer lead-free PCB board assembly which

complies with RoHS standards. At upstream, we choose PCB laminates in compliance with RoHS standards for

PCB manufacturing. Also we use lead free solder paste and related reflow/wave ovens. We strictly fulfill RoHS

requirements in light of your local regulations and don’t want to make you into any trouble on this basis.

4. Reflow and DIP soldering

The KINGRON Reflow oven, with lead free capability, has significant advantages over previous models and rich

features including a PC control software package. Several user programmable zones between preheating and

final reflow enable the machine to process all reflow profiles up to 320 deg. C, and this machine has 8 zone for

the temperature

raise up.

The reflow process can also be observed through a large glass window assisting

the operator to optimize the

process parameters. Ideal for prototyping, technology research and pre-production runs the KINGRON reflow

plat is a high tech, user friendly, reflow oven with many pre-programmed process profiles which can be easily

selected via the LCD display and keypad.

The intuitive software package enabling process parameters to be conveniently

changed, managed and

archived on a PC, completes the user friendly control features of this sophisticated desktop reflow oven.

After place all SMD components on the PCB, we will do the FA sample to the reflow soldering to check all

parameter,once confirm FA is OK, then will run mass production.

5. AOI and X-ray and QC inspection

For all the PCBA board, we will do the AOI inspection and QC inspection, for the BGA, QFN and so on footprint,

we will do all the X-ray inspection for them to ensure the quality.

6. Burning Program and In-Circuit Test

(ICT)

Our test engineers will check short circuit, voltage, current, signal transmission of PCB assembly boards

according to your ICT test plan. A professional report will be handed up to you if for any detected problems.

For batch order, we design exclusive test frames to fast the ICT test process. We are also well sophisticated

with decoding and burning program for you. Related test frame will be built to ensure products work effectively

according to your requirements.

Our SMT capability

Material Type

Selection

Min.

Max.

PCB

Size(length/width)

330*250mm

Weight

1.8KG

Assembly points

5 Millions Components / day

Material

FR-4,CEM-1,CEM-3,Aluminium core, FPC

Finished Surface

HASL,OSP, ENIG, Flash gold

Component

Chip and IC

0201

22*22

Special Size(Connector)

1.6*0.8

72mm

BGA PIN Pitch

0.4mm

1.0mm

QFP PIN Pitch

0.35mm

1.0mm

Test

ICT, Probe fly, burn-in, function test ,

temperature cycling,

Automatic Optics Inspection Machine,

X-Ray Detection Machine