- PCB Engineering

- CAM Procedures

- Gerber File

- Gerber Generation

- Pick&Place Generation

- DFM Check Item

- DFM Check Details

- PCB FAB Tutorial

- Finished Surface

- Impedance Apply

- Impedance Type

- PCB Laminates|Stackup

- Stackup with Impedance

- Capabilities

- Tolerances

- Material Comparison Chart

- Rogers Matierl datasheets

- Rogers Material Choose

- Avoid missing Feature

- HDI PCB Stackup

Free DFM Check

As a value-added option for our Assembly services, we offer Free PCB File Check, also known as Free DFM,

namely we help check your PCB design file for possible issues that may affect manufacturability. If any issues

were detected, we would get in touch immediately to solve the issue together, then schedule the PCB production

accordingly.

The DFM will be carried out from 5 aspects: Drill Checks, Signal and Mixed Layer Checks, Power/Ground Checks,

Solder Mask Checks, Silkscreen Checks. Read through the following paragraphs for more details.

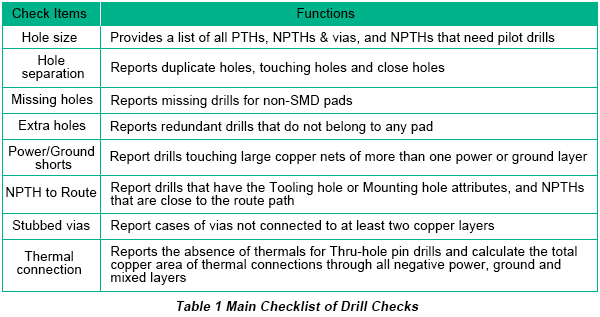

1. Drill Checks

The Drill Checks action is intended to find potential manufacturability defects in drill layers (through, buried and

blind via layers) and generate statistics on drill layers. It is intended to operate only on drill layers. It uses the drill

layer, the top and bottom layers of its drill stack and any power or ground layer in the stack. The main checklist is

displayed in the following Table 1.

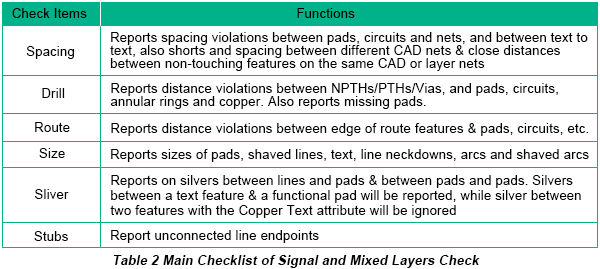

2. Signal and Mixed Layer Checks

This function is intended to find potential manufacturability defects in Signal layers and mixed layers and

generate statistics. The action can operate on any layer, but is mainly intended for signal layers. It uses the layer

itself and any NC (drill or route) layer which pierces it. The main checklist

is displayed in the following Table 2.

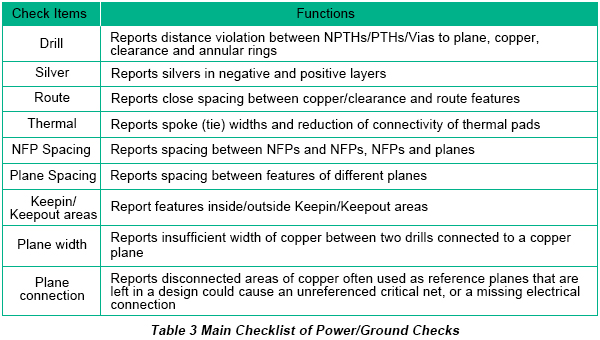

3. Power/Ground Checks

The Power/Ground Checks are intended to find potential manufacturability defects in power, ground and mixed

layers. It uses different algorithms to diagnose negative and positive power and ground layers. The main checklist

is displayed in the following Table 3.

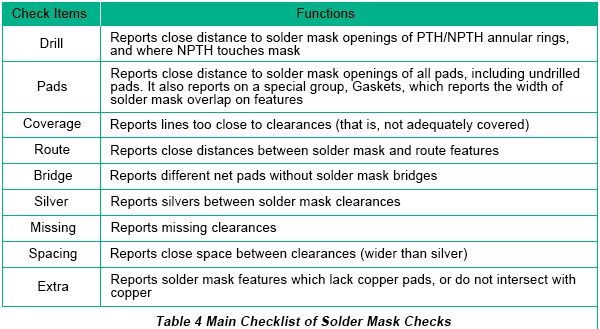

4. Solder Mask Checks

This function checks Solder Mask layers for potential manufacturability defects. Solder Mask layers are always

assumed to be negative, that is, all positive features describe clearance or the absence of solder masks. This

action also checks if solder paste has been deposited on all SMD pads. The action operates on a single Solder

Mask layer per side at a time. If more than one SMD is selected, the action will not work. The main checklist is

displayed

in the following Table 4.

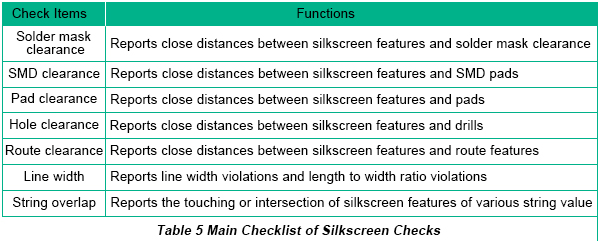

5. Silkscreen Checks

This function is intended to find potential manufacturing defects in silkscreen layers and generate statistics. The

check operates only on silk screen layers because it relies on the job matrix to find the related external copper,

solder mask and drill layers against which to check. The main checklist

is displayed in the following Table 5.

Wanna take advantage of our Free DFM option? Start from sending a quote request for your custom

PCB Assembly project to [email protected]. Make sure you include your PCB design file, BOM and other

specific requirements. Our agents will check your file and give a custom quotation within 1-2 working days.