High-Tg circuit boards (HTg)

For printed circuit boards exposed to high

thermal loads, the necessary long-term operating temperature must

be determined early on, in order to select an appropriate material.

The Tg value of the base material can be used for this purpose as a reference.

Below we have summarized the details for you.

Typical application areas

· Multilayer boards with many layers

· Industrial electronics

· Automobile electronics

· Fineline trace structures

· High temperature electronics

Tg Value

The glass transition temperature (Tg) is an

important normative dimension for the base material that determines the

temperature at which the resin matrix converts from a glassy, brittle condition

into a soft, elastic one.

The Tg value of the base material

sets here an upper boundary,

at which the resin matrix decomposes and a subsequent delamination occurs. The Tg is thus not the value

of the maximum operational temperature, but rather that which the material can

endure for only a very short time.

A guideline for a continuous thermal load is

an operating temperature approximately 25°C below the Tg.

When the glass transition temperature (Tg) is over 170°C,

it is referred to as a high Tg material.

· High Tg materials have the following properties:

· High glass flow temperature value (Tg)

· High temperature durability

· Long delamination durability

· Low Z axis expansion (CTE)

*CAF - Conductive Anodic Filament: an undesirable conducting filament in the substrate of a circuit board

Depending on the stock on hand, the materials listed may be replaced by technically equivalent or similar products. For critical tolerances, please discuss your requirements with our engineers.

CTE-z

The CTE value shows the thermal expansion of the base material. CTE-z represents the z-axis and is e.g. due to the stability of the vias, of high importance. A higher Tg value favors a low CTE-z value which represents the absolute expansion in the z-axis. Errors like pad lifting, corner cracks and cracks within the via can be prevented through a low CTE-z value.

T260 - T288 value, Td

The

decomposition temperature Td of

a resin system depends on the binding energies within the polymers, and not on

the glass transition temperature Tg. A

good indicator for this characteristic is the T260 or T288 value, which

specifies the time until delamination at 260°C or 288°C, respectively.

A very important indicator of the heat resistance is

the time-to-delamination at a certain temperature. This test is preferably

performed at 260 °C or 288 °C. The T260- or T288-value is the time to delamination

of the tested material at 260 °C or 288 °C, repectively.

Td: Temperature-of-decomposition

indicates the temperature at which the base material has lost 5% by weight and

is an important parameter for the thermal stability of a base material. Through

exceeding this temperature an irreversible degradation and damage to the

material by the decomposition occurs.

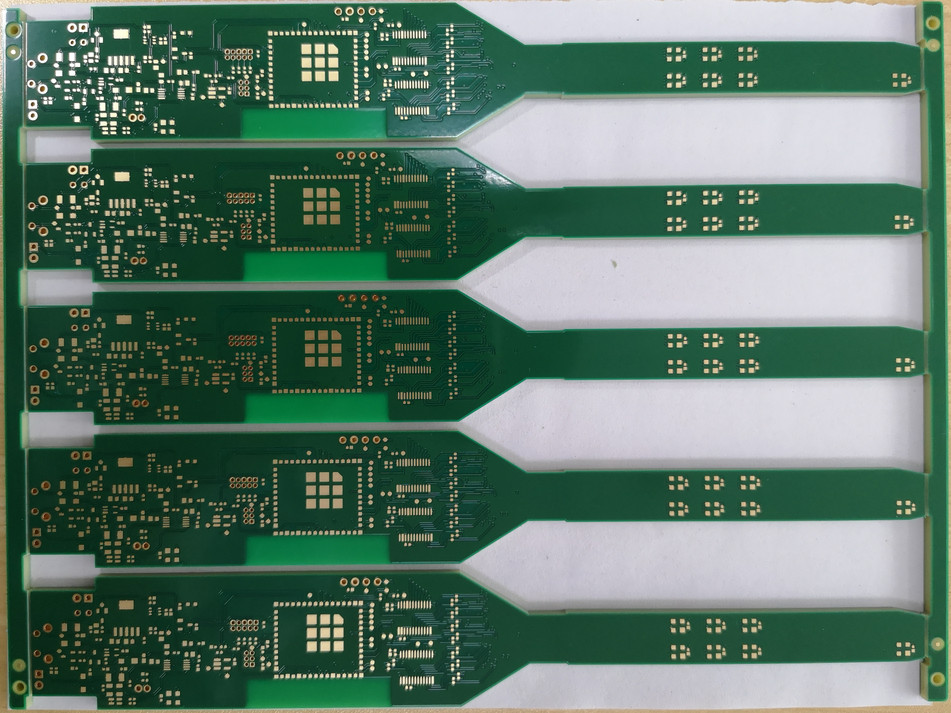

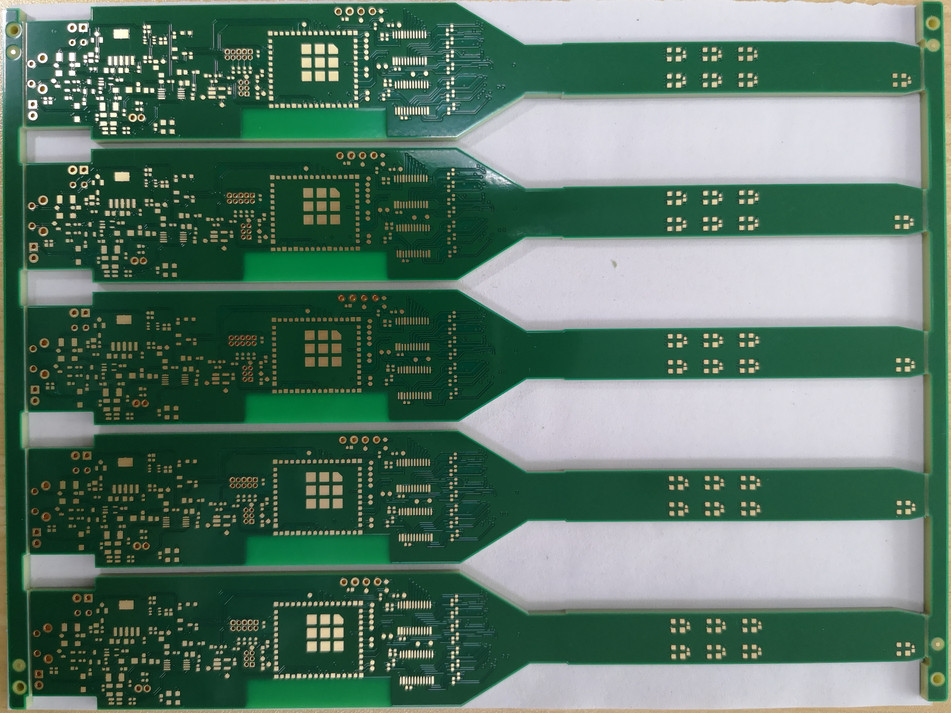

Providing the Right High-Temperature PCB for Your Applications

KINGRON offers a wide selection of high-temperature PCB products manufacturing services either with FR-4 or other high-quality heat- and temperature-resistant Tg materials. We are able to perform high-temperature PCB fabrication for automotive, industry and high-temperature electronics applications. We can manufacture High-Tg PCBs with a Tg value of up to 180°C. Following table lists some of our commonly used materials for High-Tg PCBs production.

|

Material |

TG |

Td |

CTE-z |

Td260 |

Td288 |

|

S1141 (FR4) |

175 |

300 |

55 |

8 |

/ |

|

S1000-2M (FR4) |

180 |

345 |

45 |

60 |

20 |

|

IT180 |

180 |

345 |

45 |

60 |

20 |

|

Rogers 4350B |

280 |

390 |

50 |

/ |

/ |

Regardless of the scope or complexity of your PCB application, we have the technical expertise to develop customized PC boards that meets your specific demands. Check PCB capabilities in here