- PCB Engineering

- CAM Procedures

- Gerber File

- Gerber Generation

- Pick&Place Generation

- DFM Check Item

- DFM Check Details

- PCB FAB Tutorial

- Finished Surface

- Impedance Apply

- Impedance Type

- PCB Laminates|Stackup

- Stackup with Impedance

- Capabilities

- Tolerances

- Material Comparison Chart

- Rogers Matierl datasheets

- Rogers Material Choose

- Avoid missing Feature

- HDI PCB Stackup

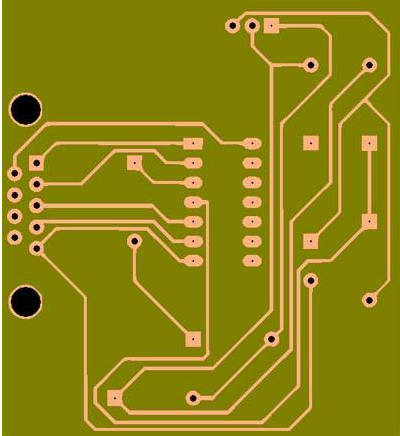

1.Board cutting

cut the whole sheet of CCL into small panel according to the array drawing of MI, then to grinder the edges and

bake them according to the manufacture instruction.

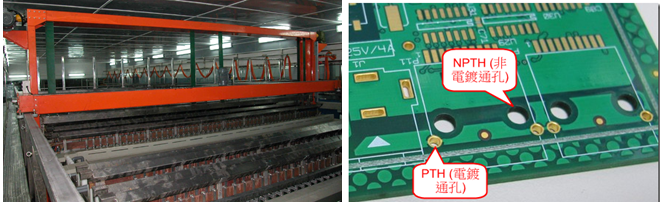

2.Drilling

To form a path for component installation and electric conductivity among PCB layers.

3. PTH

(Chemical Copper) Create a continuous copper layer in hole.

4.Panel Plating

Apply plating after PTH to avoid no copper in hole after micro-etch. Baking after plating for better

stock;

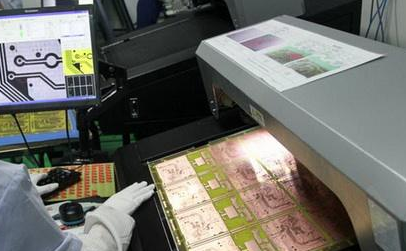

5. Outer Dry film(ODF)

Laminate dry film on clean Cu cover through hot-pressing, then transfer circuit patter artwork onto dry film by

Exposure and developing.

6. Pattern plating

Plating Cu on conductor pattern (Plating a layer Cu on circuit patterns to increase reliability of PCB

7. Outer Etching

Remove non-required copper with etching solution to obtain pattern required.

8. Outer AOI

Scan the conductor layers with any short, open, nicks,

pits. Dents. Etc.

9.Solder mask

1). Choose the correct grinding way so as to make out a clean board surface;

2). Select regulated ink with appropriate viscosity; Accurate 1st stage baking;

3). Select the appropriate exposure/imaging

10.Finished

surface

To create one coat over the outer copper surface, the type has HASL Lead free, HASL, Immersion gold,

Immersion Tin, OSP and so on.

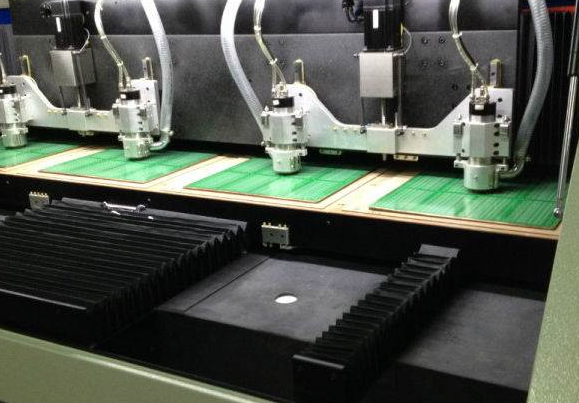

11.Routing

To uses digital control routing machine to process outline according to customers' specification

12.E-Test(Open/short)

using test fixture to electrical function of productions

13.FQC

Visual inspection was according to specification of customer, and prevent rejected boards from flow out.

Cleanliness test: Put board into solvent then test Cl-

content through OMEGA 600SMD tester.

14.FQA

Visual

inspection was according to specification of customer, and prevent rejected

boards from flow out

15. FGC

to prevent F.G being broken during transporting packing them according to customer's requirements

16. Packing/shipping

Follow customer's requirement to pack PCB.

Shipping: According to requirement of PO to ship out.

KINGRON have the rich experience on full service PCB fabrication, we provide the quick turn around lead time and