- PCB Engineering

- CAM Procedures

- Gerber File

- Gerber Generation

- Pick&Place Generation

- DFM Check Item

- DFM Check Details

- PCB FAB Tutorial

- Finished Surface

- Impedance Apply

- Impedance Type

- PCB Laminates|Stackup

- Stackup with Impedance

- Capabilities

- Tolerances

- Material Comparison Chart

- Rogers Matierl datasheets

- Rogers Material Choose

- Avoid missing Feature

- HDI PCB Stackup

Layer Stackup

Why stack-up?

With the development of electronic products, PCBs are facing more requirements including

miniaturization, low weight, high speed and capacity and multiple functions, which results in the

popularity of multilayer PCBs. Multilayer PCBs are made up by two or more PCBs which are

stacked together with reliable predefined mutual connection between them. There are at least

three conductive layers in one multilayer PCB with two layers outside and one layer synthesized

in the insulation board. With the increasing of PCB complexities and densities, it's possible for

some problems to take place such as noise, stray capacitance and cross talk when layer

arrangement gets inefficient design.

Planning the good multilayer stack-up is the most important in determining the Electromagnetic

Compatibility (EMC) performance of a product. A well designed layer stack-up can both minimize

the radiation and can stop circuit being influenced by external noise sources. Well-stacked PCB

substrates can also reduce signal cross talk and impedance mismatch issues. However, an

inferior stack-up can increase the EMI radiation, because reflections and ringing in the system as

a result of impedance mismatch which can dramatically reduce the product performance and

reliability.

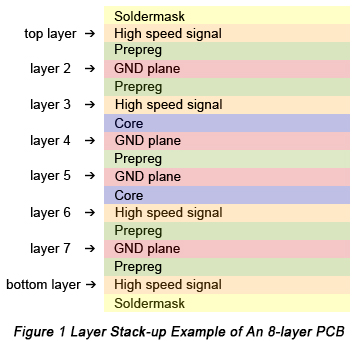

What is stack-up?

Stack-up refers to the arrangement of copper and insulating layers that make up a PCB before

starting board layout design. For multilayer PCBs, general layers include ground layer, power

plane, signal layer, high speed signal layer, solder mask and silk screen. Figure 1 is an example of

8-layer PCB stack-up.

From this figure, it's obviously clear to indicate layer distribution in PCBs follows a symmetrical or balanced

structure. Besides the 8 layers, the

spacing between layers should be taken seriously as well. To meet the

requirement of miniaturization, minimum trace spacing must be obtained while

planning layer stack-up. The space between layers can be either core or

prepreg. Multilayer boards usually consist of at least one or more cores and

prepreg. Cores are made up of a copper-plated glass-reinforced epoxy laminate

sheets. The thickness of core is in the range from 0.1mm to 0.3mm.

Prepreg is the common term for a reinforcing fabric which has been

pre-impregnated with a resin system. This resin system (typically epoxy)

already includes the proper curing agent. The main function of prepreg is its

role in stacking all layers into a whole board by high temperature stack-up.

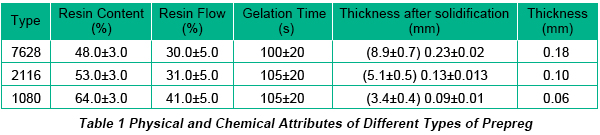

Prepreg has the following main categories: 7628, 2116 and 1080 whose physical

and chemical attributes are displayed in Table 1.

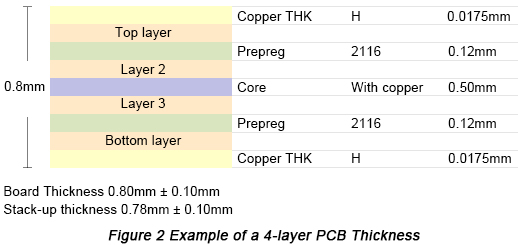

Actually, thickness of each type of prepreg isn't usually stable and some adjustments will possibly be made in order to meet the specific board thickness requirement. Some factors have

to be taken into consideration when determining the number of prepreg including thickness of

inner layer, product design thickness requirement or technique requirement, prepreg type,

practical performance and the actual thickness after stack-up trial. For example, Figure 2 shows

a 4-layer PCB thickness example.

In this example, the thickness of copper thickness is stable so that the thickness of prepreg and

core should be adjusted in order to meet the whole thickness requirement.

Some solutions to possible problems in the process of stack-up

• Interlayer offset

Resin recession groove is used in board side design instead of choked flow pad. In regards with

stack-up positioning, hot melting plus rivet plus dowel method can be used to solve stack-up

offset problem.

• Stack-up measling

In the process of board arrangement, silicon pads can be added, together with the assistance of

epoxy plate so that pressure will remain balanced, which can both help eliminating stack-up

measles and effectively control the uniformity of board thickness.

KINGRON Standard PCB Layer Stack-up

KINGRON manufactures standard multilayer boards with layers in the range from 4 to 32 layers,

board thickness from 0.4mm to 3.2mm, copper thickness from 18μm to 210μm (0.5oz to 6oz),

inner layer copper thickness from 18μm to 70μm (0.5oz to 2oz), and minimal spacing between

layers to 3mil.

Images below display KINGRON's standard stack-up capabilities and dimensions. Did not find the

layer stack-up for your custom circuit boards? Simply inform us your PCB thickness and layer

numbers at [email protected], we'll provide the corresponding stack-up very quickly.

Note: we use default layer stack-up for PCB Prototype Service. If you do not accept our default

layer stack-up, please switch to our Standard PCB Service.