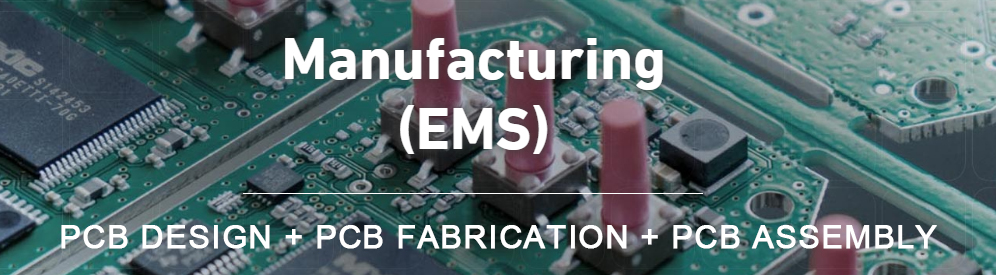

- PCB Engineering

- CAM Procedures

- Gerber File

- Gerber Generation

- Pick&Place Generation

- DFM Check Item

- DFM Check Details

- PCB FAB Tutorial

- Finished Surface

- Impedance Apply

- Impedance Type

- PCB Laminates|Stackup

- Stackup with Impedance

- Capabilities

- Tolerances

- Material Comparison Chart

- Rogers Matierl datasheets

- Rogers Material Choose

- Avoid missing Feature

- HDI PCB Stackup

| Available surfaces | |||

|

Surface

|

Thickness | Shelf life | Reflow cycles |

| HASL SnPb | >5µm | ca.12 months | 5 |

| HASL lead-free | 1-40um | ca. 12 months | 5 |

| Chemical tin | >1µm | ca. 6 months | 5 |

| Chemical silver | 0.2 - 0.3µm | ca.12 months | 5 |

| Chemical gold | 3-6µm Ni | ca. 12 months | 5 |

| ENIG | 0.05-0.1µm Au | ||

| Galvanic softgold | 4 - 6µm Ni | ca. 12 months | - |

| >1µm Au | |||

| OSP | 0.2 - 0.3µm | ca. 6 months | 2 |

HAL SnPb

HAL SnPb (lead-tin) is nowadays allowed only in certain technology fields such as

medicine and space travel. HAL is suitable for standard SMD, but shows

weaknesses in fine pitch applications. A chemical surface is preferable for

finepitch (see also HAL vs. chemical gold).

| Advantages: | Disadvantages: |

| *Good solderability | *Pads are non-planar |

| *Good reflow properties | *Not RoHS-compliant |

HAL lead-free

HAL (Hot Air Levelling) is a well-proven method to apply tin as circuit

board surface. Every assembler should be able to process circuit

boards with HAL surfaces without any problem. HAL is suitable for standard SMD, but exhibits some weaknesses for finepitch applications, for which a chemical

surface should be preferred (see also HAL vs. immersion gold).

Advantages:

Disadvantages:

*Good solderability

*Pads are non-planar

*Good reflow properties

Chemical tin

The surface chemical tin is for manufacturing reasons rarely requested any more!

Due to the rapid oxidation of the copper, the shelf life is highly dependent on

temperature and packaging. Fingerprints on the surface should be avoided at all.

Advantages:

Disadvantages:

*Absolutely flat

*Extra

charge

*Good for fine pitch

*Critical

manufacturing process

*Good for SMD

*Faster

oxidation, thus:

*Good for press-fit

*Limited

storability

Chemical silver

This circuit board surface is very similar to chemical tin, with better

properties for oxidation and contact applications. The surface is very

flat and therefore suited very well for finepitch.

Advantages:

Disadvantages:

*Absolutely flat

*Extra

charge

*Good for fine pitch

*Better

use: chemical gold

*Good for SMD

*Good for press-fit

*Better shelf life than chemical tin

Chemical gold (ENIG)

Just as with chemical tin and chemical silver, chemical gold is an extremely flat

circuit board surface, and has very good oxidation properties. It is perfectly

suited for finepitch and bonding (aluminium wire) applications. Due to popular

demand, Multi-CB can offer chemical gold in pooling service (cheaper price). Chemical gold is also called ENIG

(Electroless Nickel Immersion Gold).

Advantages:

Disadvantages:

*Absolutely flat

*Possible

extra charge

*Very good for fine pitch

*Very good for SMD

*Good wetting characteristics

*Good for press-fit

*Good storability

*Available in Pool-Service